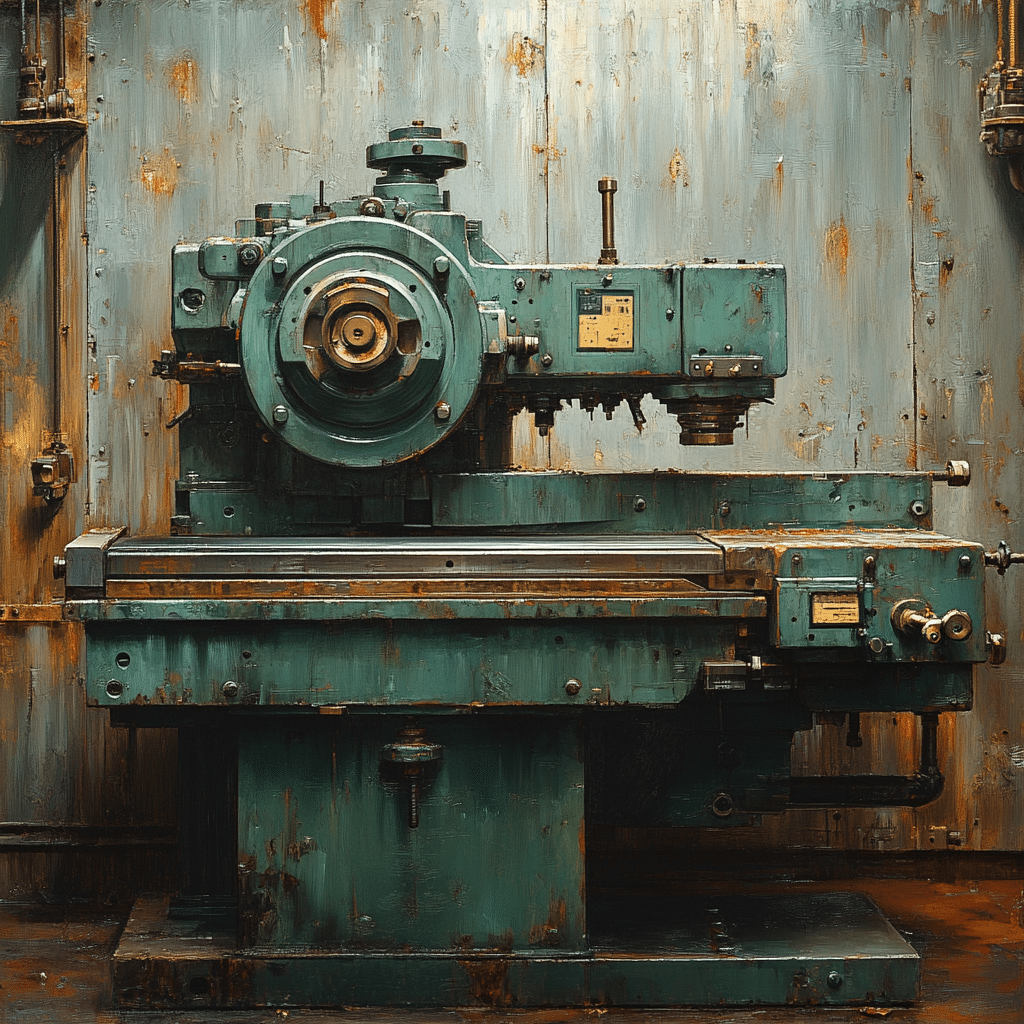

The recent Russian lathe accident has sent tremors through the manufacturing landscape, shaking the foundation upon which safety protocols stand. This shocking incident took place in a well-known Siberian factory, where a misfiring lathe wreaked havoc and raised immediate concerns around workplace safety standards. What went wrong? From inadequate equipment checks to a glaring lack of operator training, let’s delve into the startling details that reveal the underlying issues contributing to this preventable catastrophe.

The Anatomy of the Russian Lathe Accident: What Went Wrong?

Investigations into the Russian lathe accident reveal a trifecta of neglect: a failure to maintain equipment, insufficient operator training, and the absence of critical safety protocols. When jaws drop at the mention of what transpired, it’s essential to dig deeper to understand the mechanics of this disheartening event.

Top 5 Key Factors That Contributed to the Accident

Diving into the chaotic maelstrom of the Russian lathe accident, we identify five pivotal factors that spiraled into tragedy:

The lathe failed to meet internationally recognized safety standards, akin to lapses seen in other notorious global industrial accidents. Well-established brands like Haas Automation have long emphasized the importance of stringent guidelines, which were clearly neglected in this case.

Experts from organizations like Horry County highlighted that risk assessments were either rushed or omitted entirely. This failure connects to incidents around the globe that have left companies scrambling to tighten their safety measures. Companies like Caterpillar bolster their operations with thorough frameworks that are crucial in avoiding chaos.

With ineffective communication among the workforce, first responders struggled in immediate situations. This systemic issue is often seen in factories that shy away from implementing clear hierarchies, contrasting sharply with companies like Boeing which thrive on structured communication.

The lack of contemporary safety gear, such as emergency shut-off devices and even simple channel lock pliers for quick adjustments, ramped up the incident’s seriousness. It’s like going into battle without armor; it’s just a bad idea.

Early assessments indicated that regulatory bodies had twiddled their thumbs on enforcing safety measures in the area. This laxity mirrors other sectors where negligence led to calamities. If authorities don’t step up, the ripple effects will be felt across the board.

Recycling Versus Safety: The Dilemma in Brass Shell Casings

Following the Russian lathe accident, the conversation around the recycling of brass shell casings has heated up. Facilities face an ongoing conflict: the pressing need to recycle materials versus the undeniable priority of worker safety. This clash raises poignant questions about how facilities can balance efficiency with stringent safety protocols.

Case studies from companies like Brass Products Company showcase that effective recycling initiatives can exist hand-in-hand with rigorous safety measures. But when corners get cut, the whole operation teeters on a razor’s edge. Safety risks need to be addressed head-on to ensure that the strive for sustainability doesn’t come at the cost of human lives. Think of it this way—if the operators aren’t safe, how can you expect processes to be efficient?

Horry County Bookings: A Broader Context

Ironically, this accident mirrors incidents stemming from Horry County bookings, where industrial mishaps sometimes land individuals in hot water for negligence. As repercussions unfold in Russia, authorities in both regions could benefit from drawing lessons from one another. Prioritizing accountability for industrial safety will generate a ripple effect, aiming for a safer working environment globally.

The dialogue around these tragedies must focus on establishing precedents that enhance workplace safety while maintaining operational efficiency. By learning from the past, industry leaders can forge a path toward a comprehensive safety framework—a world where we don’t have to douse flames after they’ve sparked.

Lessons Learned: Enhancing Future Safety Protocols

In the wake of the startling Russian lathe accident, several valuable lessons emerge that industries worldwide must heed:

The Path Forward: A Safer Industrial Landscape

It’s crystal clear: the shocking details uncovered in the Russian lathe accident reveal systemic issues that extend far beyond any single factory. As industries worldwide embark on the journey of improvement, the dual focus on safety and efficiency becomes non-negotiable.

By prioritizing robust safety measures, we’re not just shielding workers from harm; we’re sustaining operational integrity and harvesting progress toward a new era of resilience. Just as any savvy fashionista would scout for the best materials, so too must industry leaders ensure that all threads weave together seamlessly for a safer tomorrow.

In conclusion, while catastrophes like the Russian lathe accident send shivers down the spines of many, they also offer invaluable lessons that, when embraced, can lead us toward a safer and more efficient industrial landscape. As we collectively shift gears, remembering that worker safety paves the way for longevity must become our mantra. Safe worksites are not only ethical—they’re also smart business. So, the quest for fiery creativity in industry must always be coupled with a steadfast commitment to preserving human life.

Russian Lathe Accident: Shocking Details Uncovered

A Close Look at Machinery Mishaps

The Russian lathe accident has sent shockwaves through the engineering community, revealing just how critical safety protocols are in the manufacturing industry. Did you know that lathes themselves have been around since ancient Egypt? They’ve developed immensely over the years, but the danger they pose remains significant. Just like those summer Movies that thrill you with suspense and sudden turns, the mishaps that can occur in machine work are no less dramatic and can lead to life-altering consequences—much like a powerful plot twist.

Interestingly, the sheer volume of accidents in the workshop isn’t just a matter of poor design. According to studies, many of these incidents arise from insufficient training. Imagine trying to operate a TI-84 calculator without any instruction—confusing, right? That’s what many workers face when they lack formal training on complicated machinery like lathes. With the stakes this high, one can only say “спасибо” thank You in Russian) to all those who’ve championed better safety measures that prevent future accidents.

The Hidden Dangers

In examining the circumstances surrounding the Russian lathe accident, it’s crucial to recognize that external factors often play a key role. Weather conditions, like humidity and temperature shifts, can affect machinery performance. In fact, these elements can become obstacles, similar to when you’re trying to find a Walmart Supercenter near me after losing your way—I mean, it’s all about navigating hurdles while staying calm.

Moreover, many accidents occur not because of the machinery but due to operator error, often exacerbated by fatigue. Like discovering the unexpected taste of fentanyl, which you might never anticipate, operators can find themselves caught off guard by overwhelming challenges. Machinery can often afford no mistakes, proving that precision is vital to avoid disastrous accidents. Just as the valley river center stands out as a beacon of fun and activity, safe workplaces should shine in the same regard—ensuring everyone goes home whole and healthy.

In recounting the shocking details of the Russian lathe accident, it’s evident that much can be learned about vigilance and preparation. Remember, a little trivia can go a long way in emphasizing safety. With a focus on education—whether it’s through improving practices or even understanding your favorite summer movies—you can help build a safer future in engineering.